Для механизации производства сдобных и простых сухарей применяются специальные машины для формования и резки сухарных плит. Рис. 3.40. Машина для жгутового формования тестовых заготовок сухарных плит Для механизации прочих производственных операций используется...

Для механизации производства сдобных и простых сухарей применяются специальные машины для формования и резки сухарных плит. Рис. 3.40. Машина для жгутового формования тестовых заготовок сухарных плит Для механизации прочих производственных операций используется...

Машины для производства хлебных крекеров. Хлебные крекеры являются новым видом сухих завтраков, продуктом, готовым к употреблению. Они производятся из сухарной крошки (паниро- Рис. 3.44. Экструдер для производства хлебных крекеров войной муки) с добавлением соли,...

Машины для производства хлебных крекеров. Хлебные крекеры являются новым видом сухих завтраков, продуктом, готовым к употреблению. Они производятся из сухарной крошки (паниро- Рис. 3.44. Экструдер для производства хлебных крекеров войной муки) с добавлением соли,...

Машины для производства хлебных крекеров. Хлебные крекеры являются новым видом сухих завтраков, продуктом, готовым к употреблению. Они производятся из сухарной крошки (паниро- Рис. 3.44. Экструдер для производства хлебных крекеров войной муки) с добавлением соли,...

Машины для производства хлебных крекеров. Хлебные крекеры являются новым видом сухих завтраков, продуктом, готовым к употреблению. Они производятся из сухарной крошки (паниро- Рис. 3.44. Экструдер для производства хлебных крекеров войной муки) с добавлением соли,...

Хлеб, являясь наиболее массовым штучным продовольственным грузом с наименьшим сроком реализации, требует жестких санитарных режимов, слабо выдерживает механические воздействия, особенно в первые часы после выпечки. С учетом этого важная роль должна отводиться...

Хлеб, являясь наиболее массовым штучным продовольственным грузом с наименьшим сроком реализации, требует жестких санитарных режимов, слабо выдерживает механические воздействия, особенно в первые часы после выпечки. С учетом этого важная роль должна отводиться...

Хлеб, являясь наиболее массовым штучным продовольственным грузом с наименьшим сроком реализации, требует жестких санитарных режимов, слабо выдерживает механические воздействия, особенно в первые часы после выпечки. С учетом этого важная роль должна отводиться...

Хлеб, являясь наиболее массовым штучным продовольственным грузом с наименьшим сроком реализации, требует жестких санитарных режимов, слабо выдерживает механические воздействия, особенно в первые часы после выпечки. С учетом этого важная роль должна отводиться...

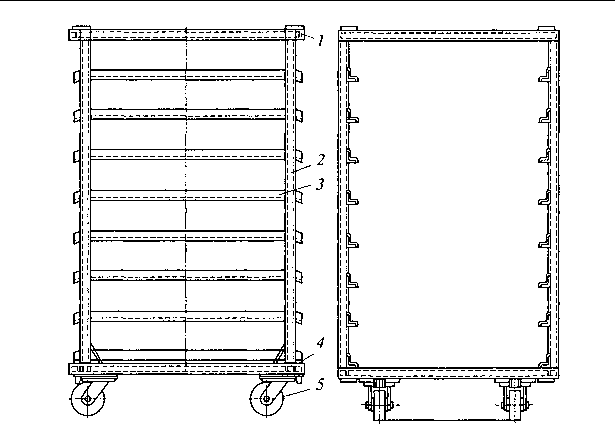

С сортировочного стола хлебные изделия направляют в лотковые или безлотковые контейнеры. Для лотковых контейнеров используются трех- или четырехбортные лотки с решетчатым (для ржаных, ржано-пшеничных, формовых и подовых сортов) или сплошным (для батонов,...

С сортировочного стола хлебные изделия направляют в лотковые или безлотковые контейнеры. Для лотковых контейнеров используются трех- или четырехбортные лотки с решетчатым (для ржаных, ржано-пшеничных, формовых и подовых сортов) или сплошным (для батонов,...

Останні коментарі